Instrument Calibrations

Most of the calibration data is taken from the array manager and from the sound acquisition module. However, PAMGuard will ask a few questions about HOW the instrument was calibrated, when it was done and who is responsible.

There are two dialogs associated with calibration. The first asks for a calibration method and has the following fields:

- Method: Must be one of the following options:

- Reference hydrophone

- Manufacturer�s specification

- Piston phone

- Other calibrated source

- Unknown

- Serial number: Hydrophone serial number

- Quality: Quality assurance value:

- unverified: The calibration has not been verified

- valid: The calibration has been validated as per the quality assurance process

- invalid: The calibration was found to be invalid during quality assurance

- QA Comment: Textual description of the quality assurance process.

- Calibration method: Textual description of the Method.

The second calibrations dialog asks for:

- Calibration date: Date the calibration was performed.

- Update frequency: Must be one of the following:

- as-needed: No updates are planned, but if a change is needed the calibration will be updated (defaul)t

- unplanned: There are no plans to ever update the record.

- yearly: A yearly review will be conducted to ensure that the record is valid.

- Technical Person / Data Manager: These two types of data have the same fields and detail who was responsible for the calibration and who is responsible for maintaining the record of the calibration. In many cases, this may be the same person and copy buttons allow the fields to be duplicated.

- Name: Responsible party�s naem

- Organisation: Organisation to which the party reports

- Position: Responsible party�s title

- Email: Email contact information

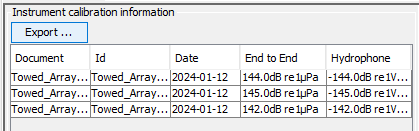

Fill in as much information as you can! If the export is successful, a record will show for each hydrophone (or sensor) in your instrument array in the calibration information table: